Why our aviation blanket is laminated rather than quilted.

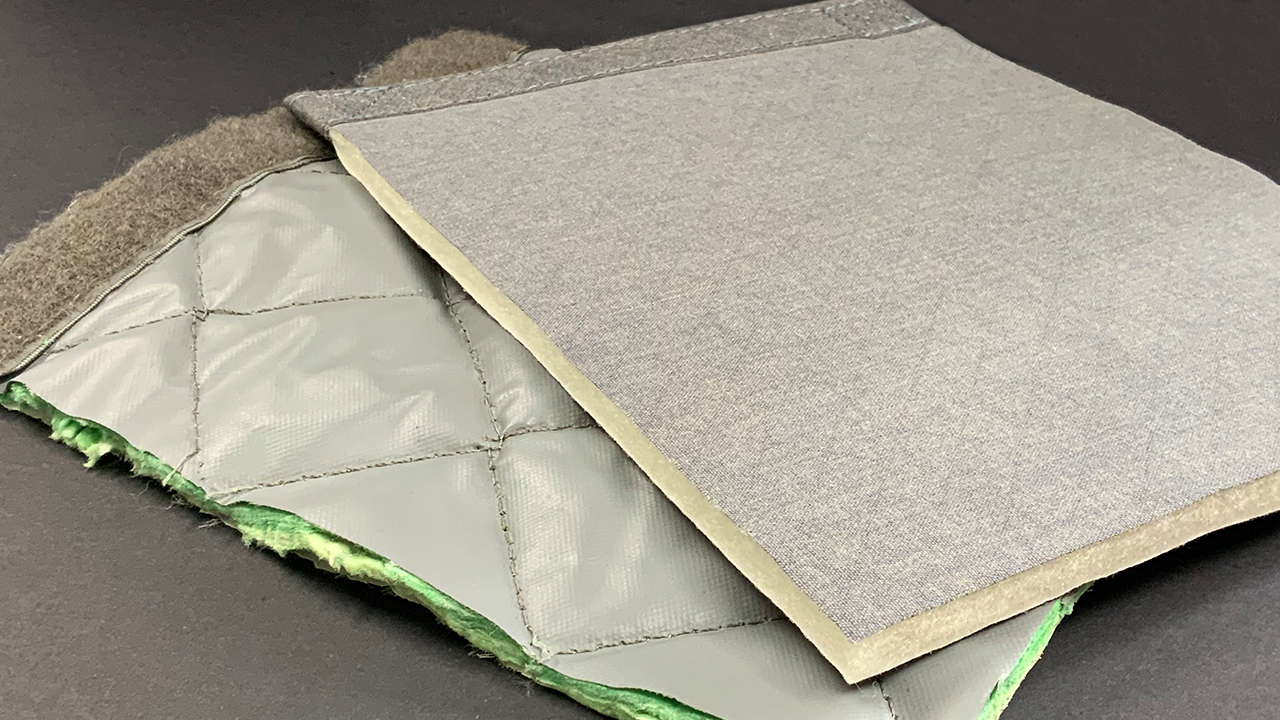

Old Blanket (LEFT) vs. Cocoon ITAB

Stitching layers of textiles together causes seen and unseen problems, but it’s far easier to do than lamination. Lamination effectively turns multiple layers into a single layer. However, it’s an incredibly difficult process because there are so many variables - the type of facing and backing fabrics, the internal layers, the type of glue, the amount of glue, the lamination method.

Having spent years getting lamination right, we know first-hand how challenging it is. Too little glue and you get wrinkling and uneven adherence. Too much glue and the membrane doesn’t perform as well. And some fabrics just don’t play well with others. We tried over 150 different iterations before landing on the right combination of elements for our aviation blanket.

So why go through all that time, effort, and painstaking work? Because it makes a significant difference to blanket performance. Every perforation of an aviation blanket degrades its performance.

Quilting produces thousands of needle perforations, which allow moisture and fluids to seep into the blanket. As a result, the blanket gets heavier and heavier with use - not only adding weight to the aircraft, but causing the blanket to droop. Those absorbed fluids also trap moisture and contaminants, causing mold, mildew, and corrosion.

Quilting also degrades both the acoustic and thermal properties of a blanket. All those little perforations are pathways for sound waves, leading to higher decibel levels. In addition, quilting compresses the insulating layer of a blanket, making it less thermally-efficient.

We admit that after about the 75th failed attempt at lamination, it would have been very tempting to go the quilting route. But we didn’t want to simply modernize aviation blankets, we wanted to revolutionize them.

To learn more about this breakthrough blanket technology, click here to download the brief.